TURNKEY EPC SOLUTIONS

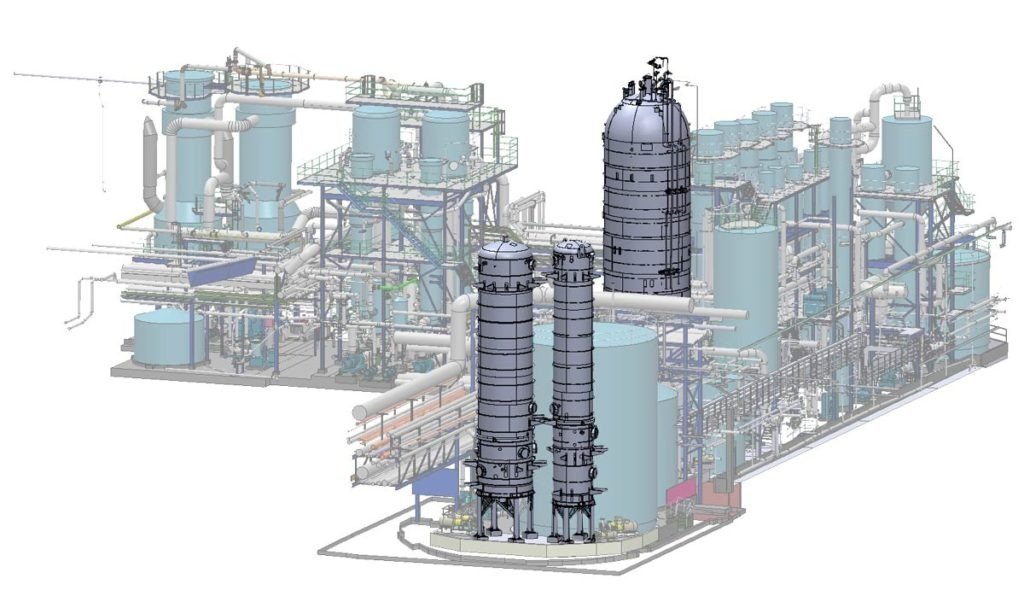

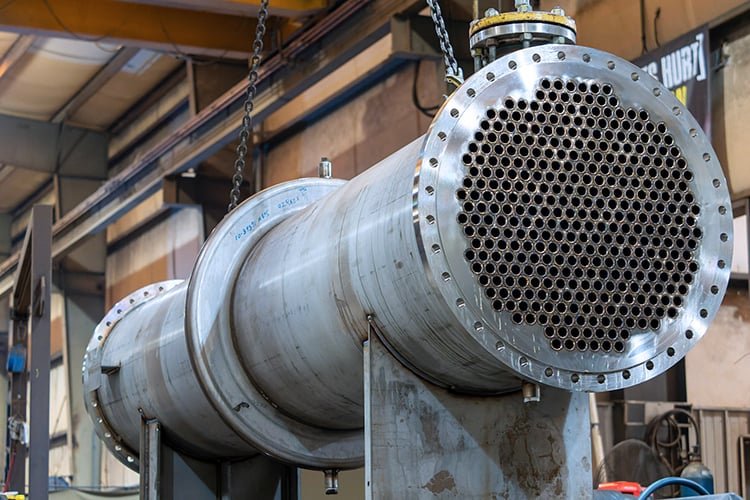

WAGO Engineering specializes in the design, engineering, and fabrication of process equipment for the Oil, Gas, and Energy industries worldwide. With core expertise in shell and tube heat exchangers, pressure vessels, and distillation columns, WAGO Engineering has developed robust capabilities that enable the delivery of complex, code-compliant equipment even under the most demanding operating conditions and challenging environments.

Our commitment to delivering high-quality, custom-engineered process equipment makes us the preferred partner for clients seeking expertise in the design, fabrication, and commissioning of shell and tube heat exchangers, pressure vessels, and distillation columns for the Oil, Gas, and Energy sectors.

Project Management

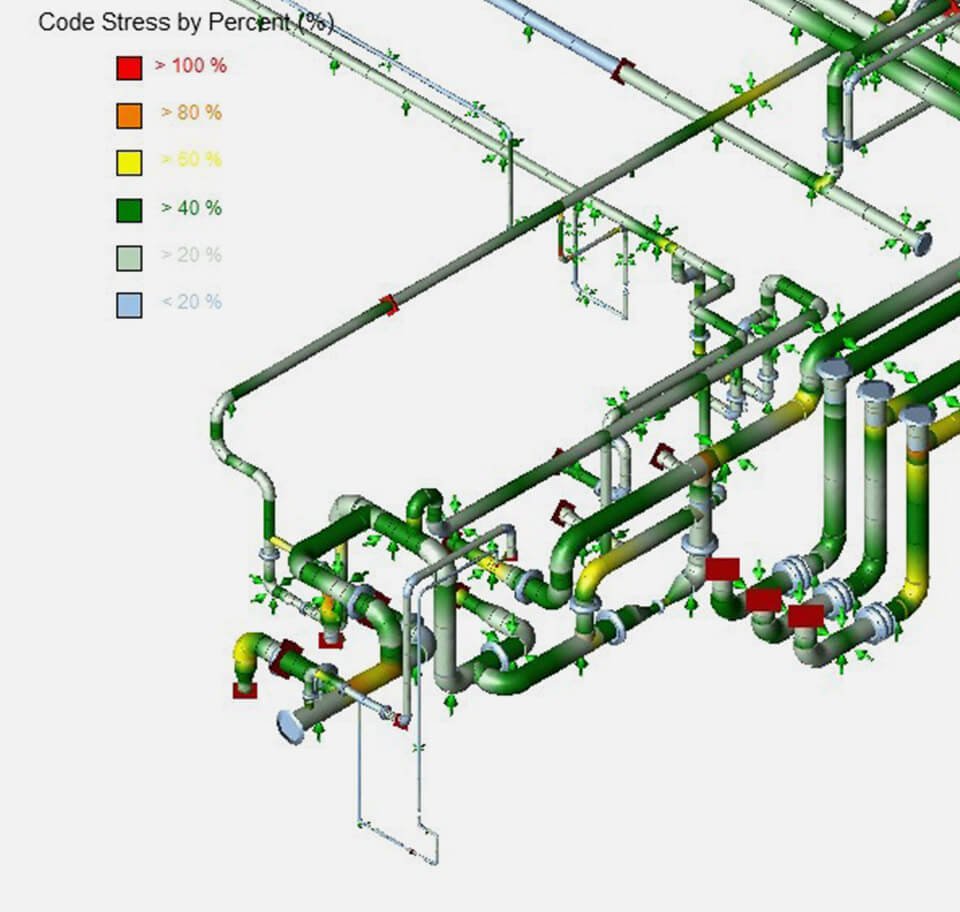

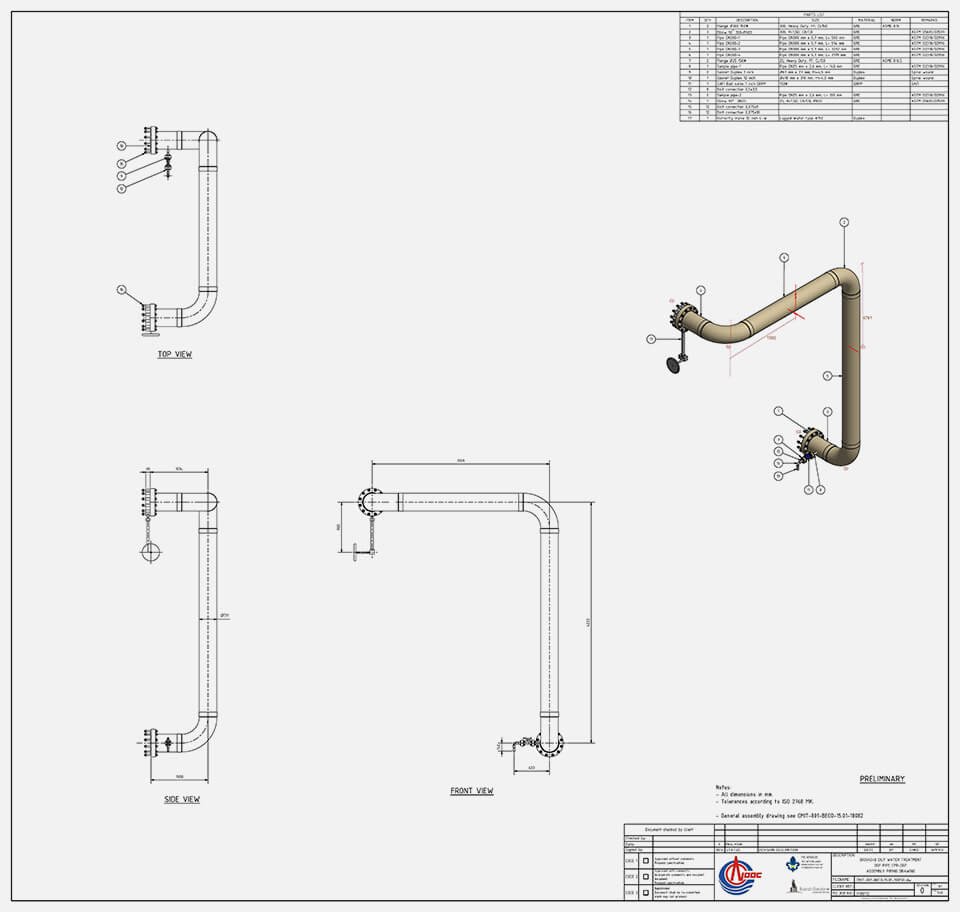

We pride ourselves on delivering tailored engineering and fabrication solutions that help our clients define equipment specifications, optimize design choices, and ensure efficient project execution. Throughout the fabrication and delivery process, our experts employ advanced design, simulation, and quality assurance tools to maximize reliability, performance, and the value of our clients’ investments.

Understanding that each project has unique requirements, we adapt our fabrication processes and testing protocols to align with client specifications, operational objectives, and the specific challenges of their facilities. Our standardized procedures are highly flexible, allowing seamless integration with client quality systems and site installation practices.

Procurement

At WAGO Engineering, our skilled procurement and expediting team plays a critical role in supporting clients with the timely acquisition of process equipment and materials, ensuring adherence to budget and project schedules without compromising quality. Being headquartered in China gives us a distinct advantage, allowing direct access to a vast network of high-quality manufacturers and suppliers, competitive pricing, and rapid sourcing for both greenfield and brownfield projects. Our procurement services are fully tailored and cover vendor technical evaluations, sourcing, expediting, and supply chain management—all aimed at maximizing value and reliability for our clients.

Leveraging China’s manufacturing ecosystem and our global network of OEM partners across Asia, the Americas, and Europe, we can deliver high-quality heat exchangers, pressure vessels, and distillation columns at short notice. This capability allows us to consistently provide optimal value, reinforcing WAGO Engineering as the preferred partner for procurement and fabrication of critical process equipment.

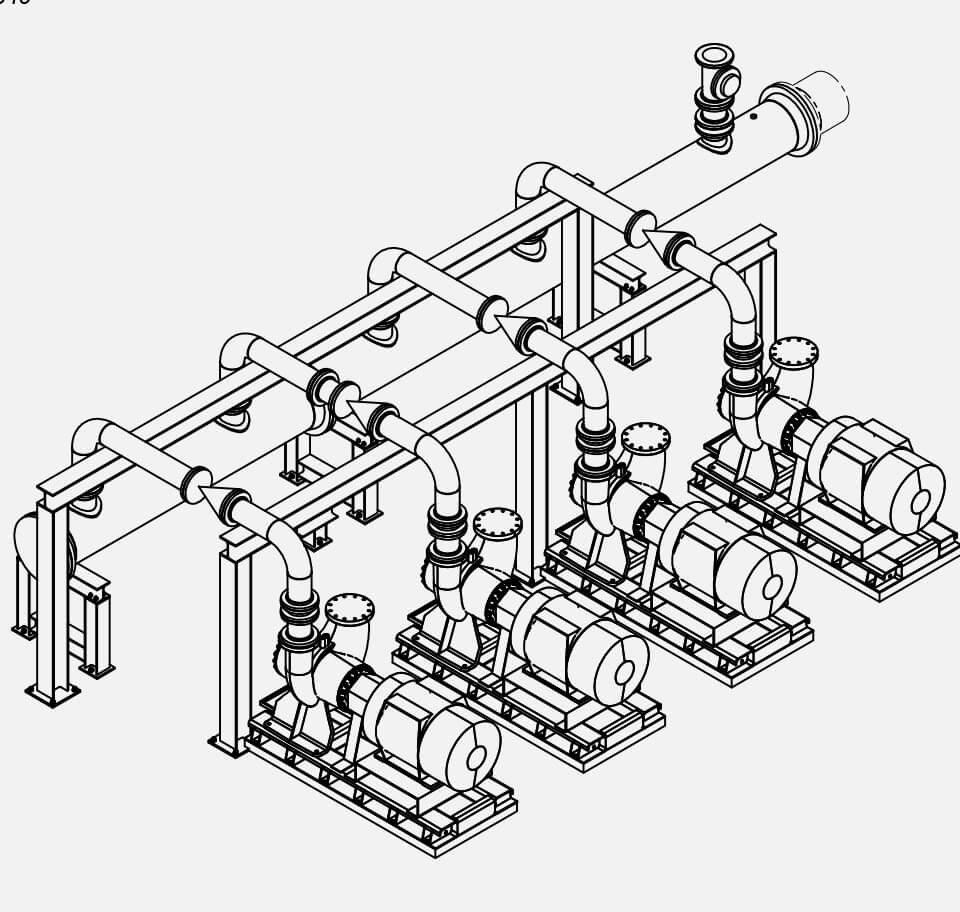

Fabrication

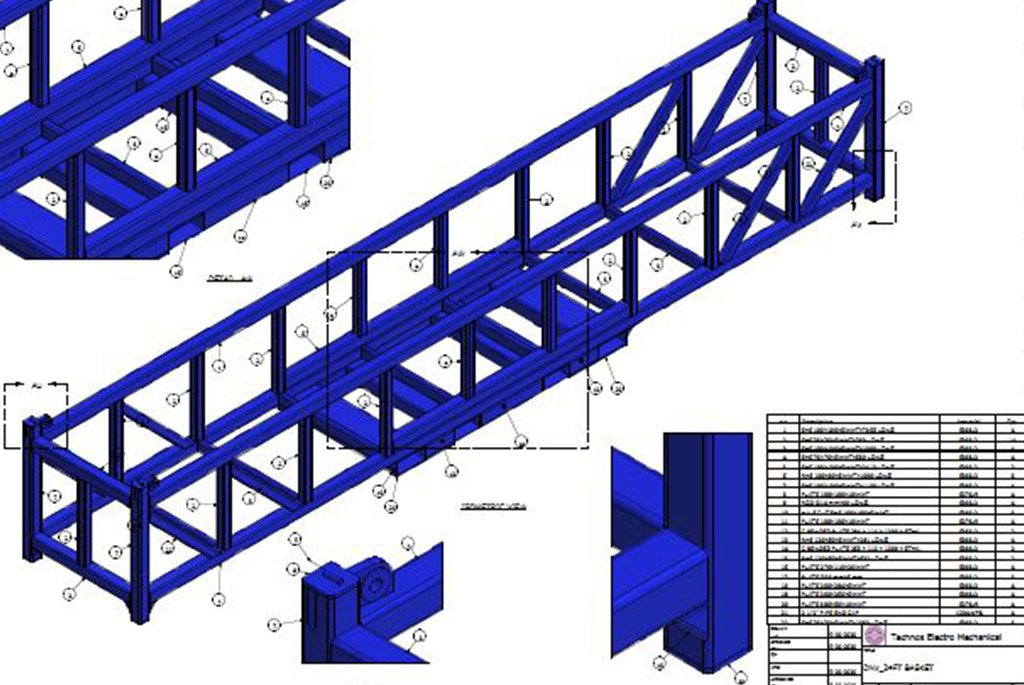

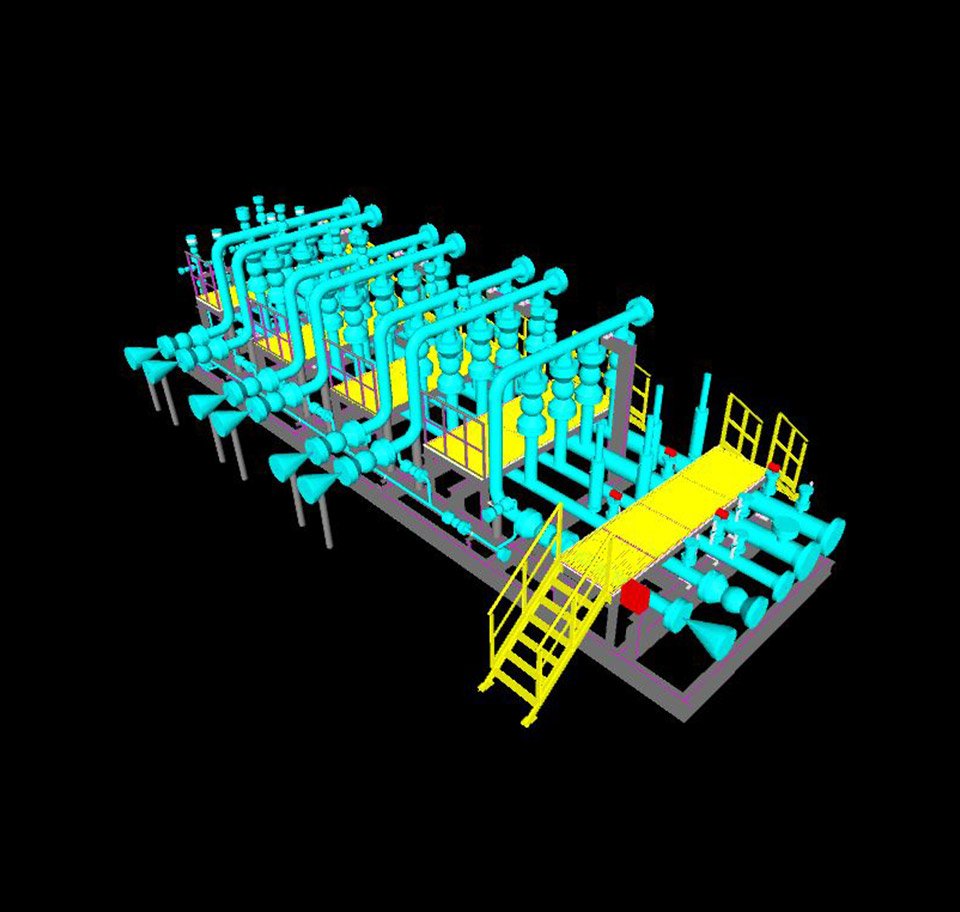

We have established a state-of-the-art fabrication facility in China to execute large-scale projects efficiently and within the shortest possible timelines. Our ASME-certified workshops operate under the latest ISO procedures, with fabrication carried out by experienced personnel and monitored through a combination of independent ASME inspectors and our internal QA/QC team.

By implementing modular designs tailored to project requirements, we maximize fabrication work within the workshop, minimizing potential delays and cost overruns that can arise from on-site challenges. Close coordination between our engineering and production teams ensures a low margin of error, high production rates, and delivery of high-quality shell and tube heat exchangers, pressure vessels, and distillation columns.

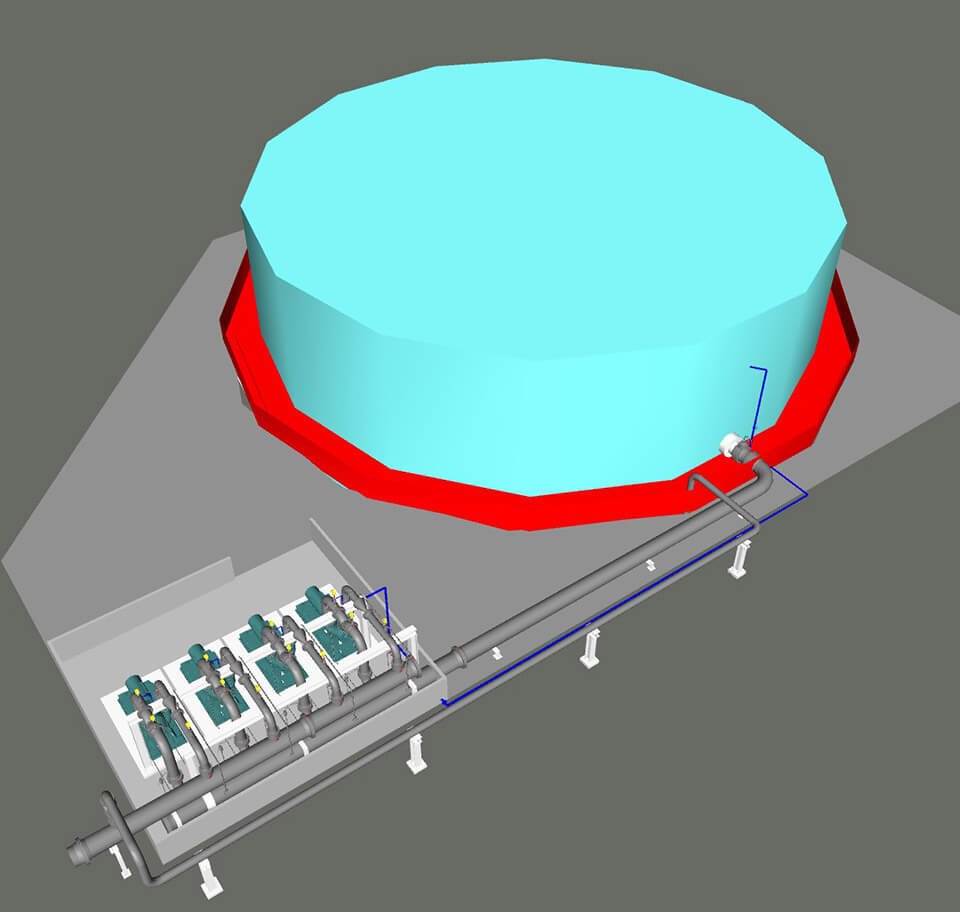

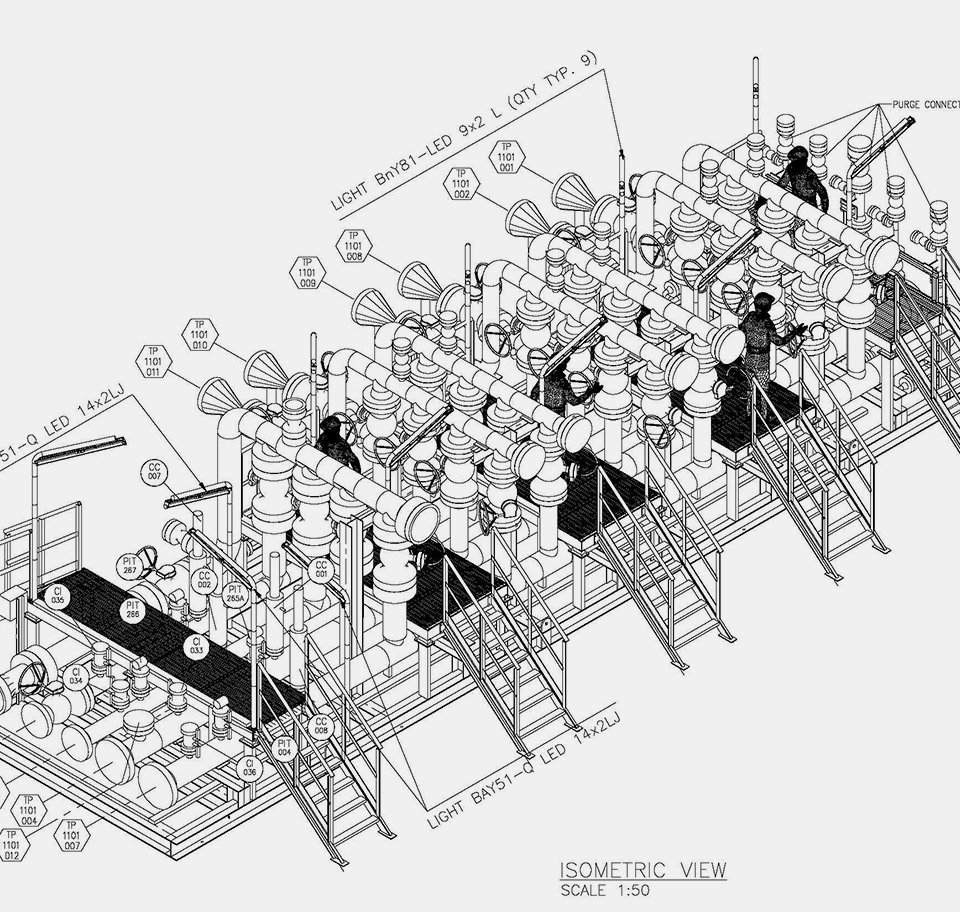

Construction

By leveraging our experienced in-house construction and commissioning team, we efficiently execute site installation and integration of process equipment. Our strategy involves early mobilization of key personnel to the project site, enabling streamlined coordination across all phases of installation, testing, and startup. Through meticulous planning and modular fabrication in our workshops, we ensure that a substantial work front is available on-site while fabrication activities continue in parallel, allowing us to deliver accelerated project schedules and high-quality outcomes for our clients.

Pre-commissioning & Commissioning

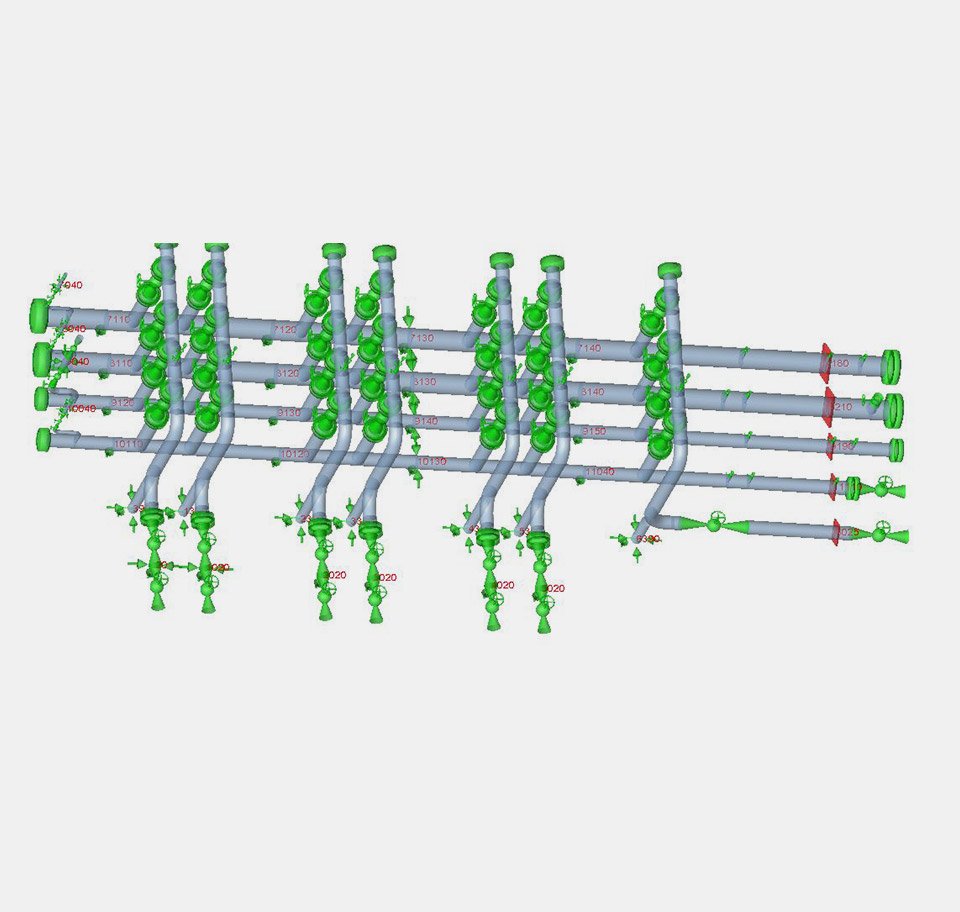

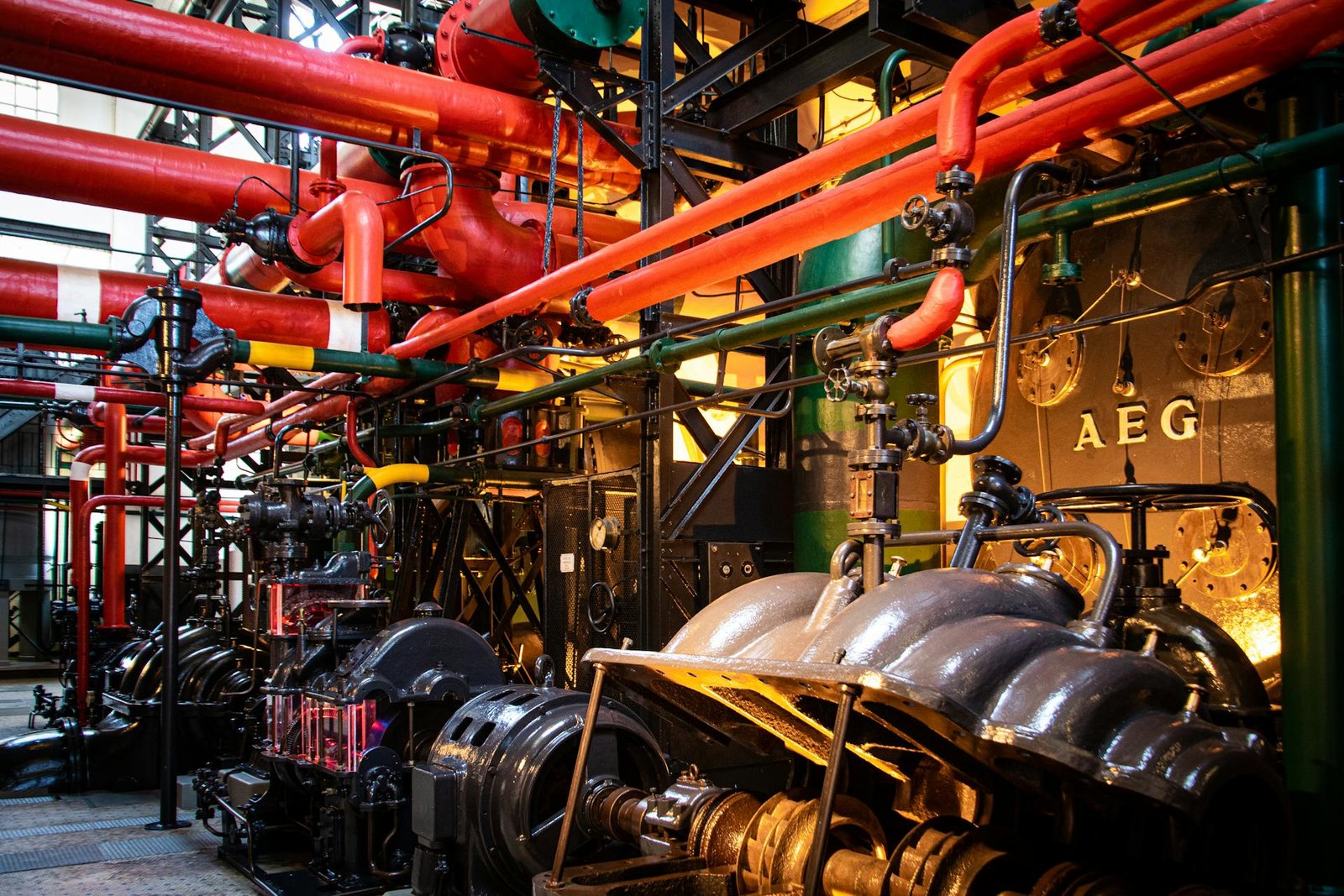

WAGO Engineering maintains a highly skilled team to deliver comprehensive pre-commissioning and commissioning services across the entire project scope. During the pre-commissioning phase, we systematically verify the integrity, readiness, and interconnectivity of all systems, including piping, instrumentation, electrical, and control systems, while preparing detailed documentation to support a seamless commissioning process.

The commissioning phase involves coordinated functional, safety, and performance testing, system integration, and thorough validation to ensure the plant operates efficiently and safely. Our experienced engineers also provide essential training for client operations personnel, enabling smooth startup and long-term reliable operation of the facility.