WAGO  Engineering

Engineering

WAGO Engineering & Equipment Supplies

OUR EXPERTISE

WAGO Engineering prides itself in being a one-stop solutions provider for our clients, assisting them through each phase of their project, from conceptualization all the way to commissioning.

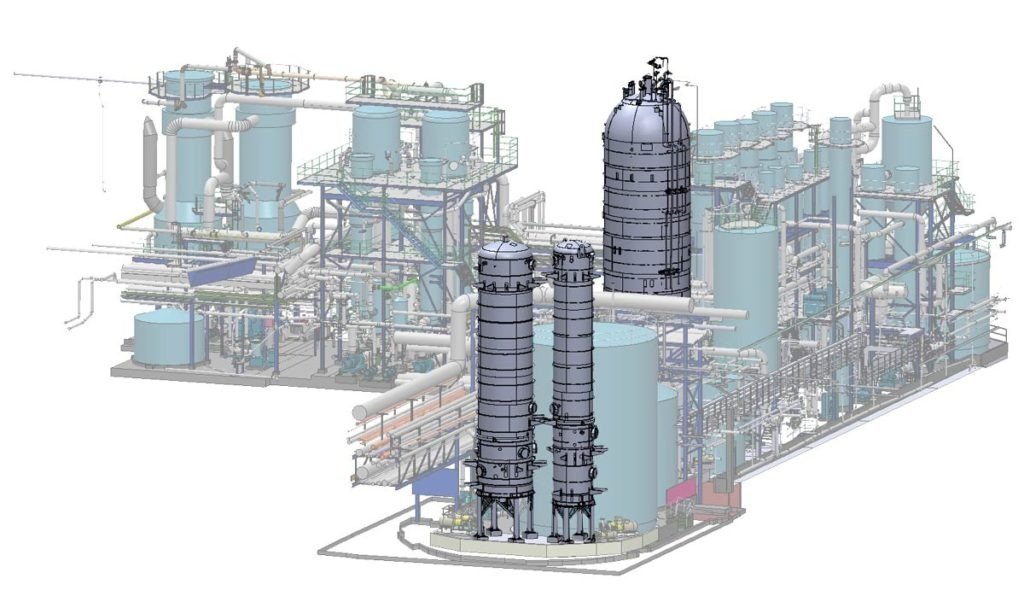

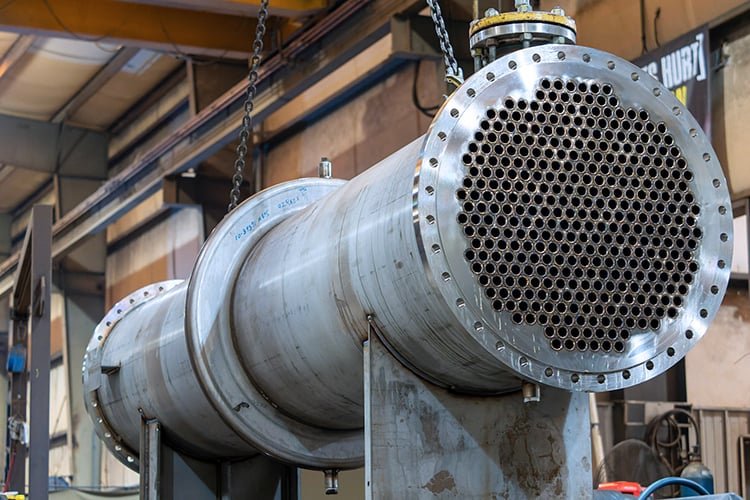

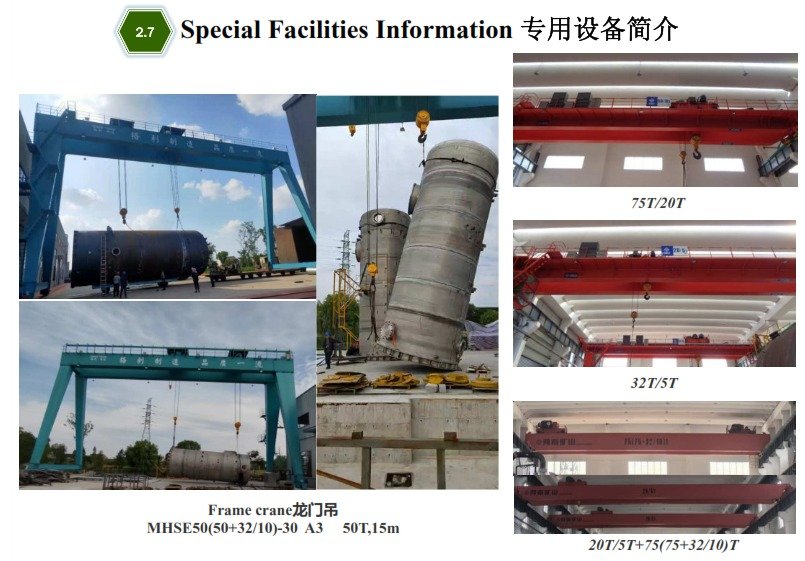

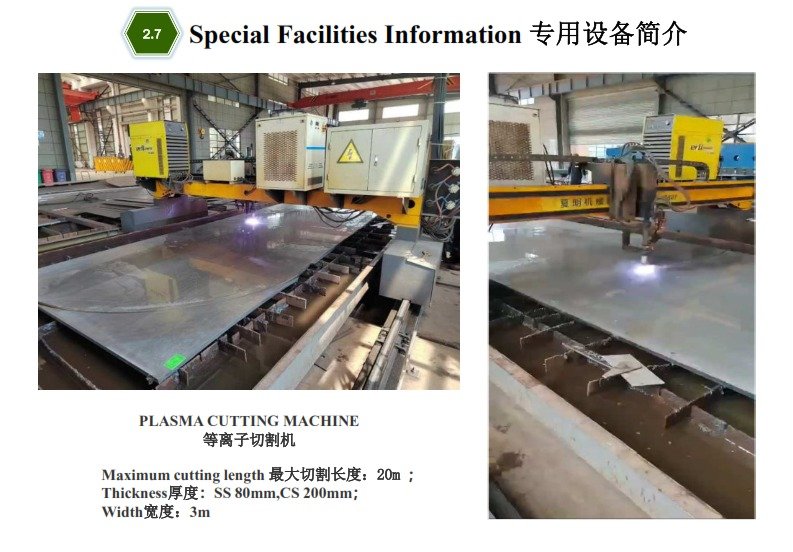

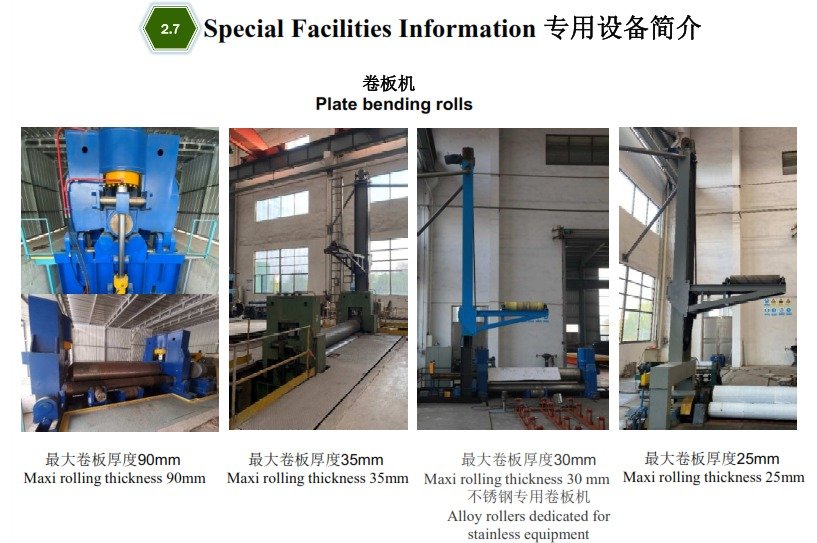

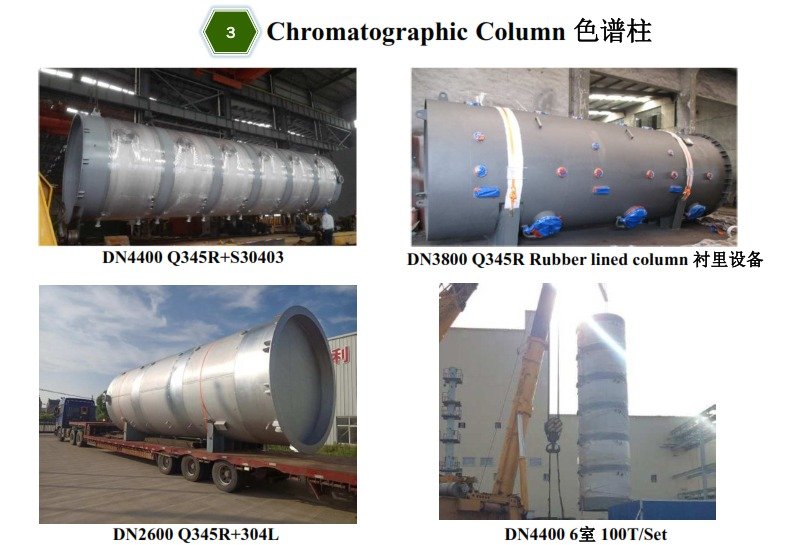

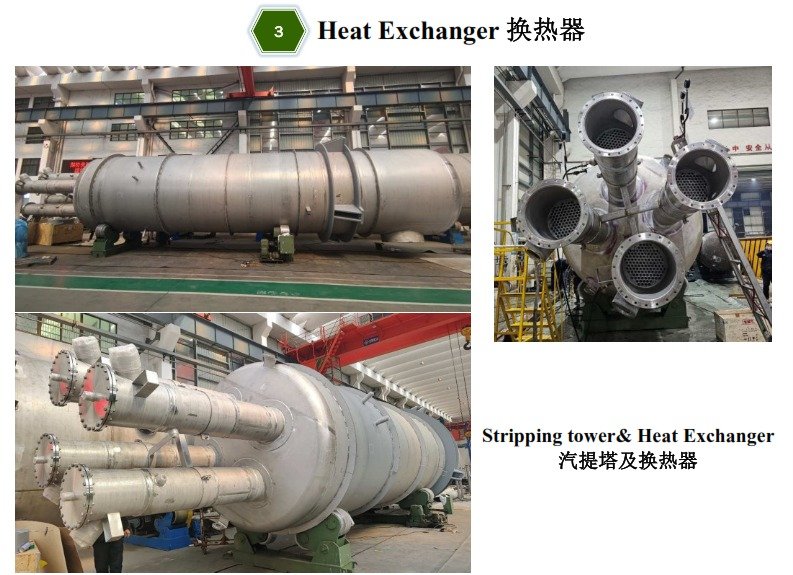

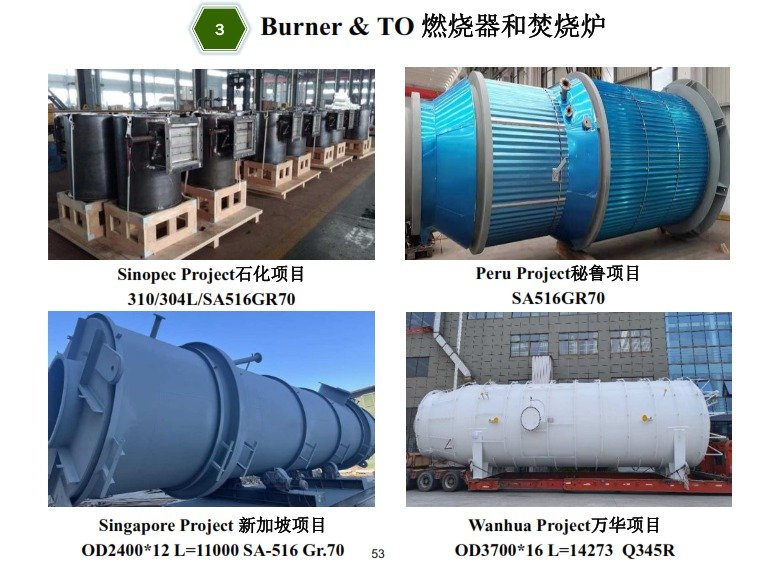

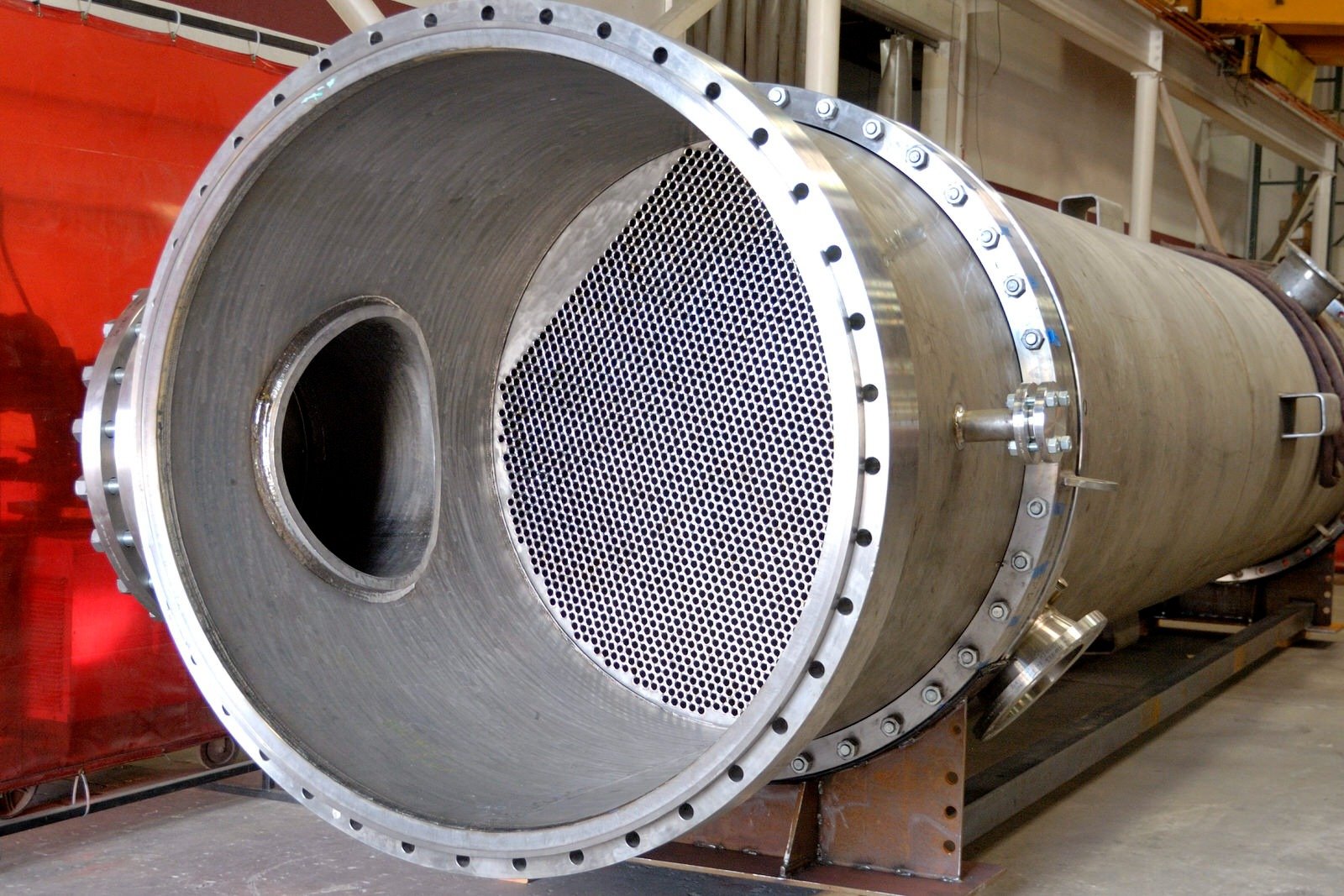

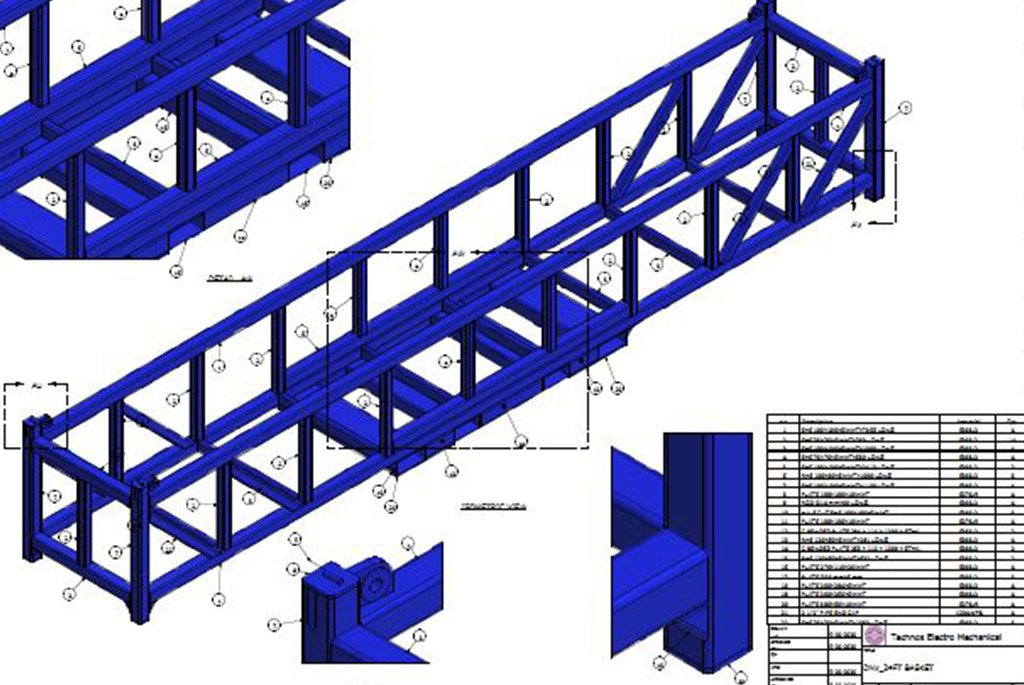

Our ASME- and ISO-certified fabrication facilities specialize in the manufacture of shell and tube heat exchangers, pressure vessels, and distillation columns in full compliance with international design codes (ASME Sec. VIII, TEMA, API, and other applicable standards). Fabrication is carried out using qualified welding procedures, certified welders, and carefully selected metallurgy to suit process requirements. All equipment undergoes dimensional checks, non-destructive examinations (RT, UT, MT, PT), hydrostatic testing, and functional shop testing to verify integrity and performance prior to dispatch. Upon completion, the units are prepared for transport through our logistics partners and delivered to site, ready for installation and integration into the plant.

OUR SERVICES

OUR RECENT PROJECTS

Let me show HOW i do

OUR RECENT PROJECTS

ENGINEERING, PROCUREMENT AND FABRICATION OF 25 SET OF EXCHANGERS

ENGINEERING, PROCUREMENT, FABRICATION OF 57 SET OF EXCHANGERS

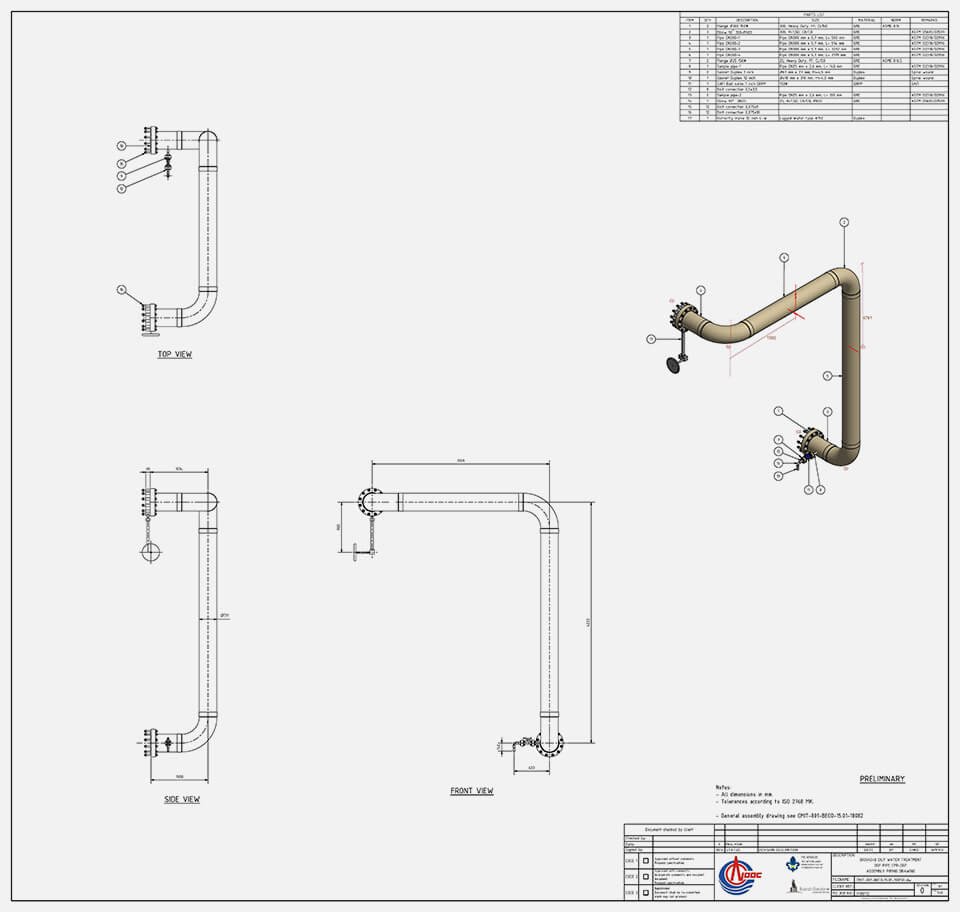

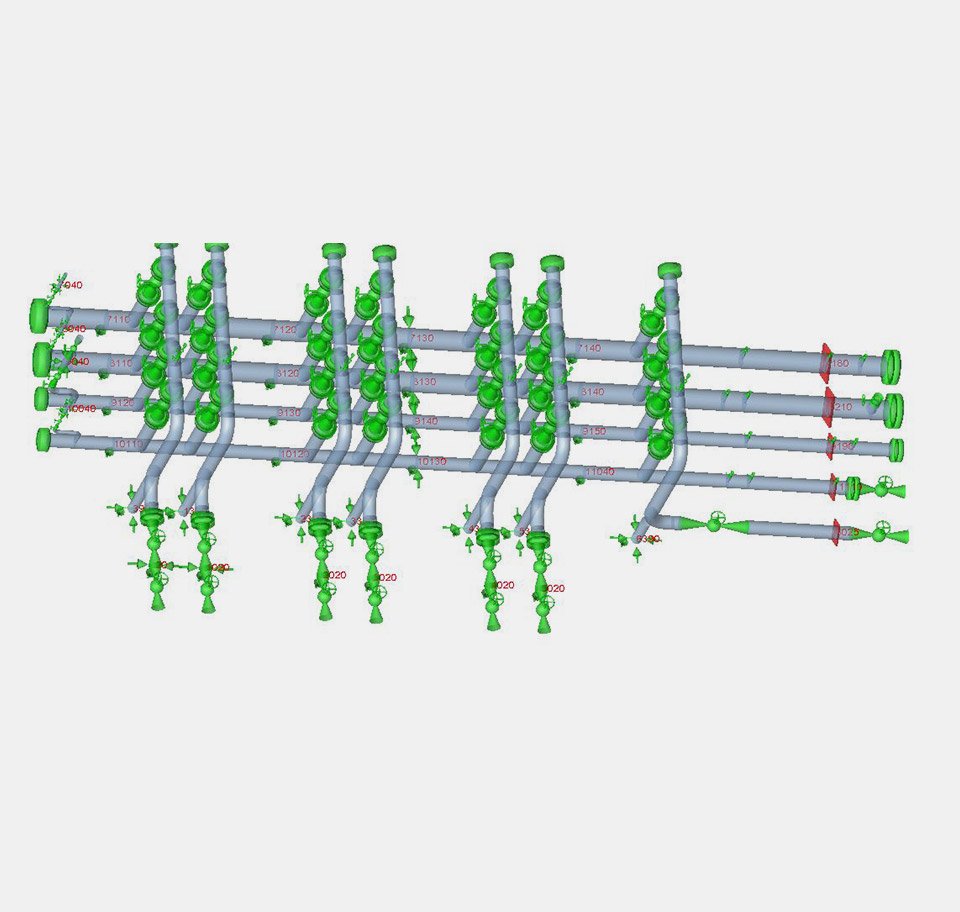

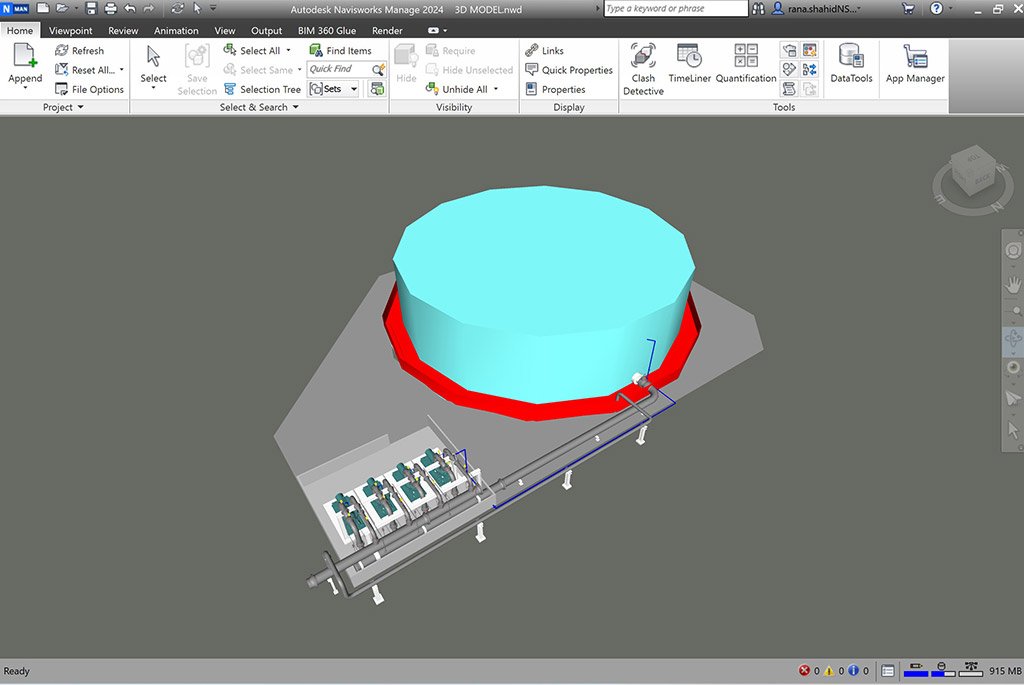

Engineering Design of Gathering Manifold Skid

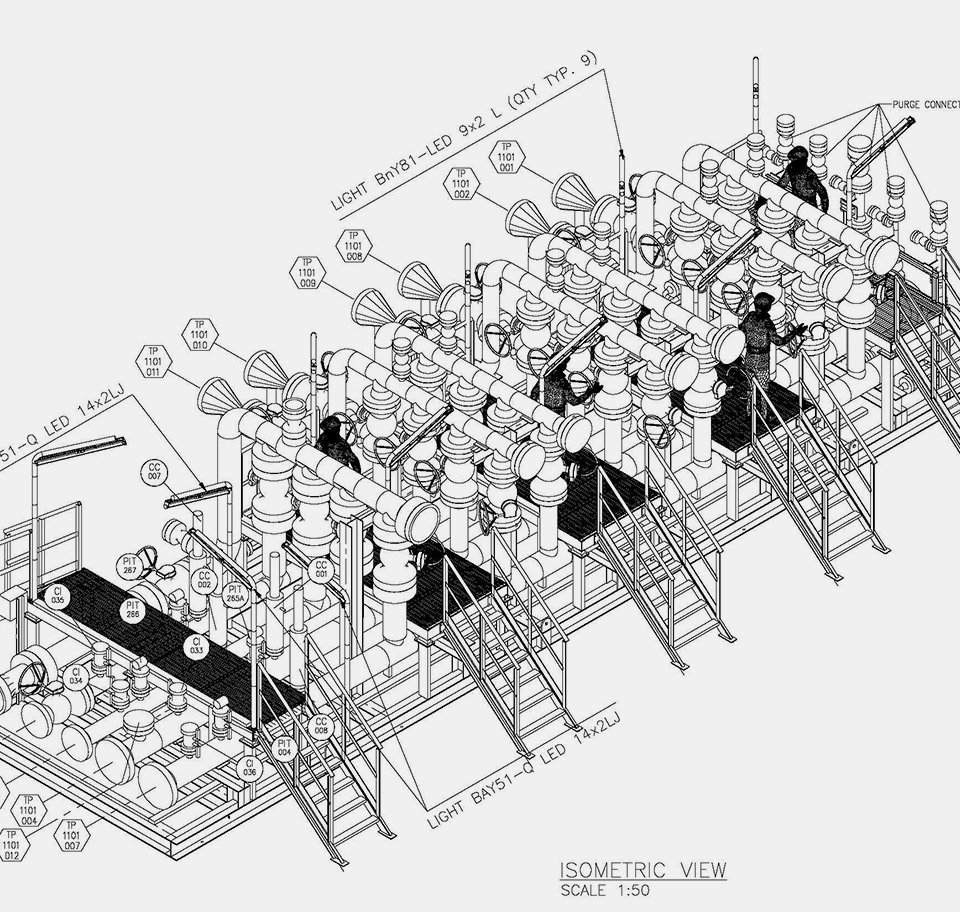

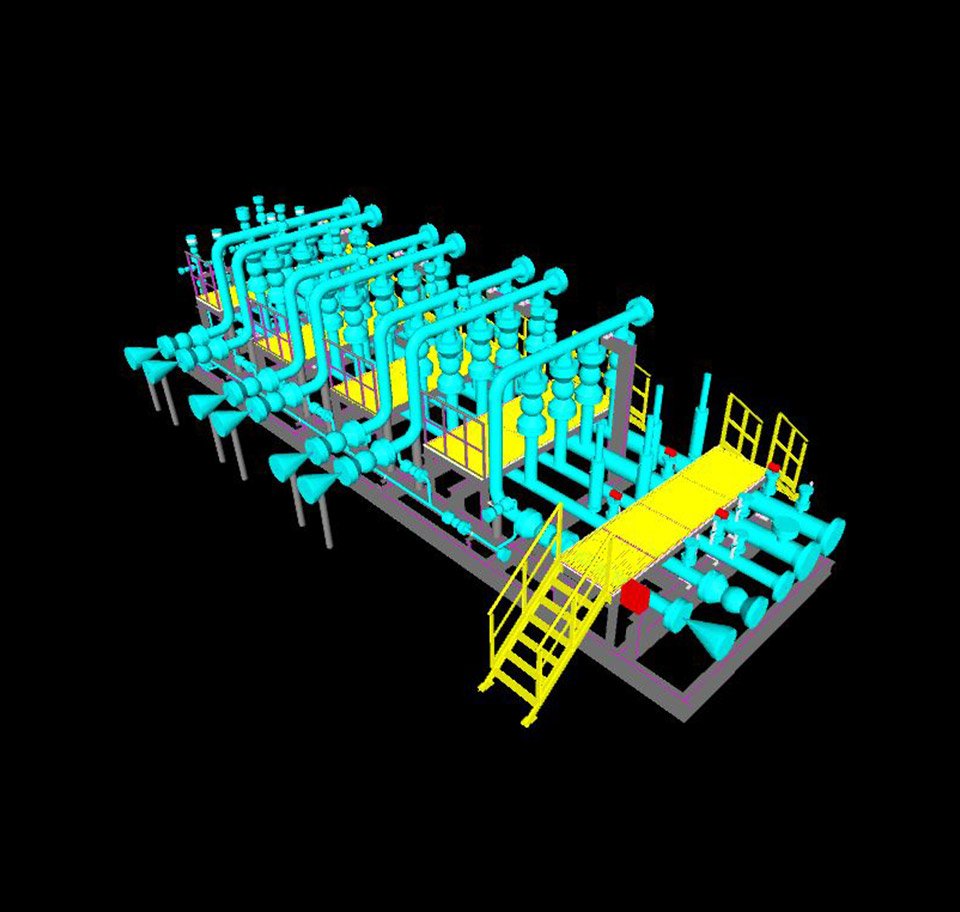

Engineering Design of MEG Package

Mechanical Design of DNV Baskets

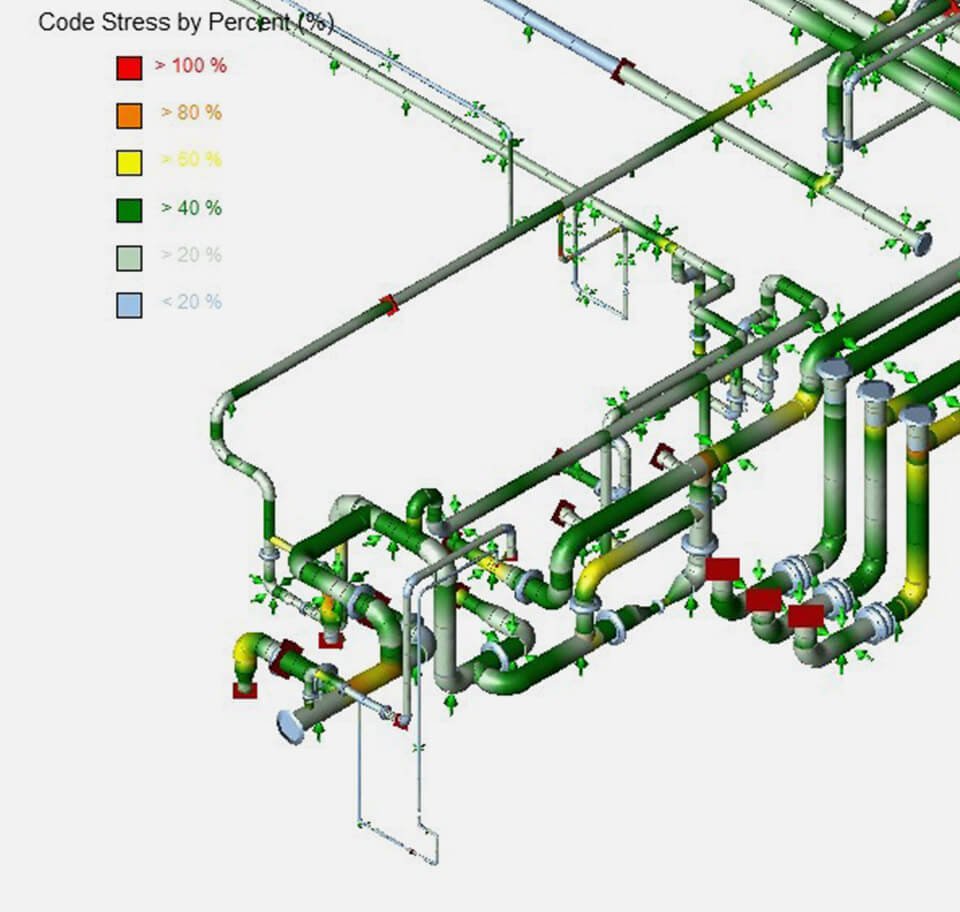

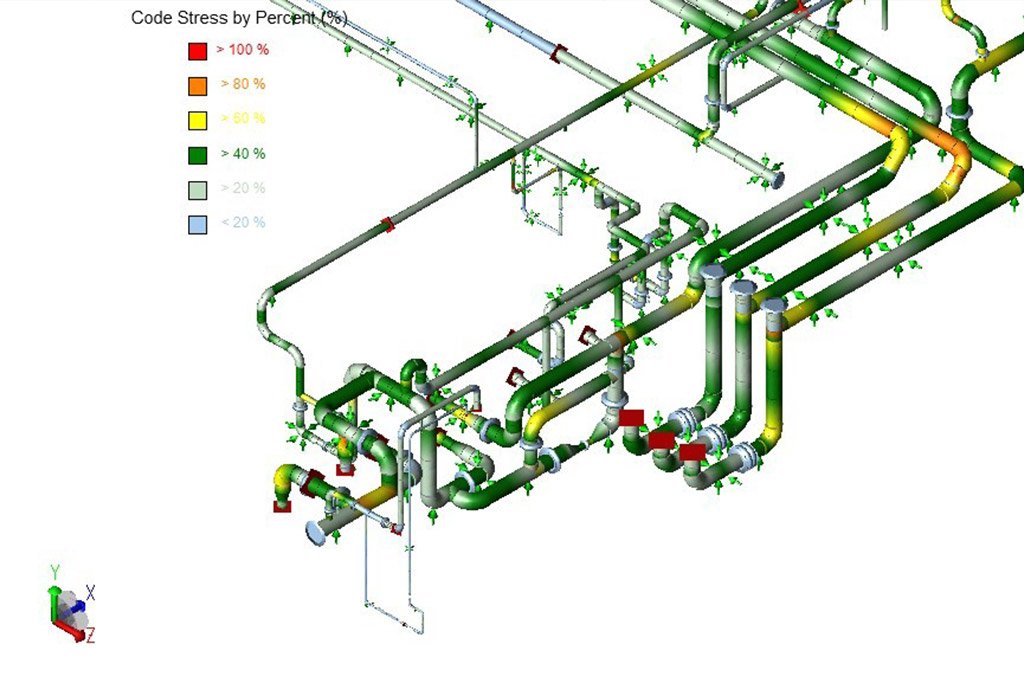

Stress Analysis of HP Steam Boiler and Turbine Piping

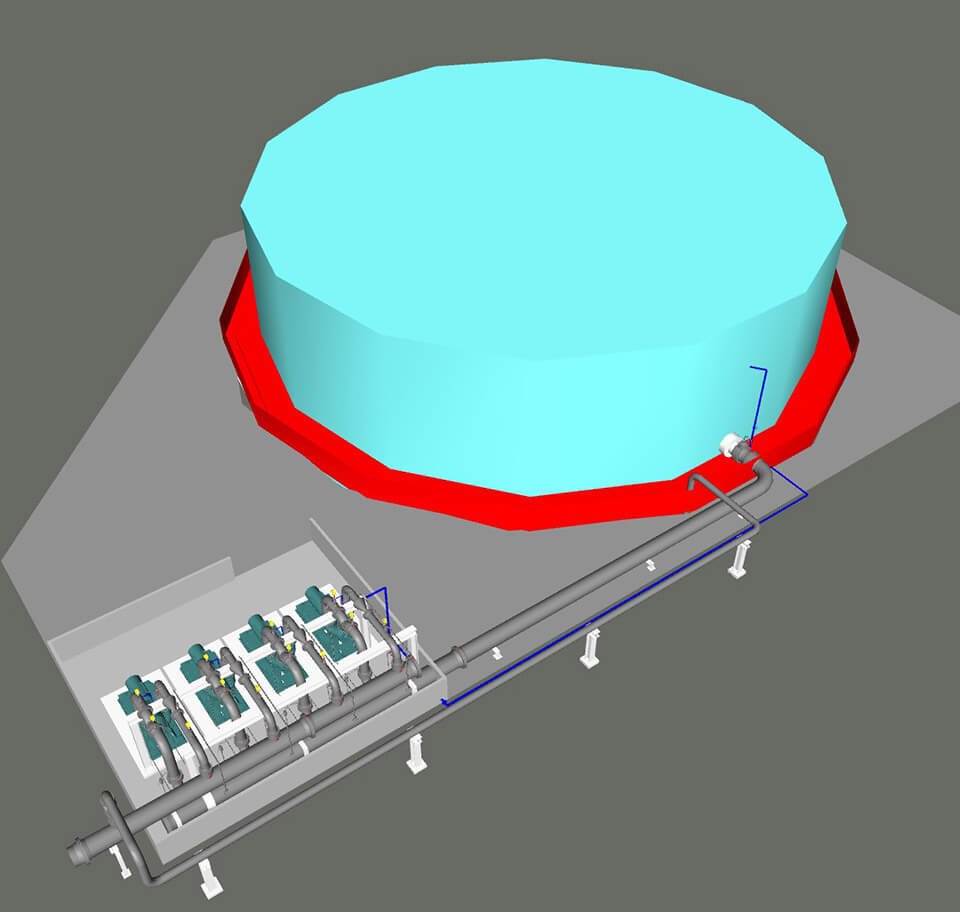

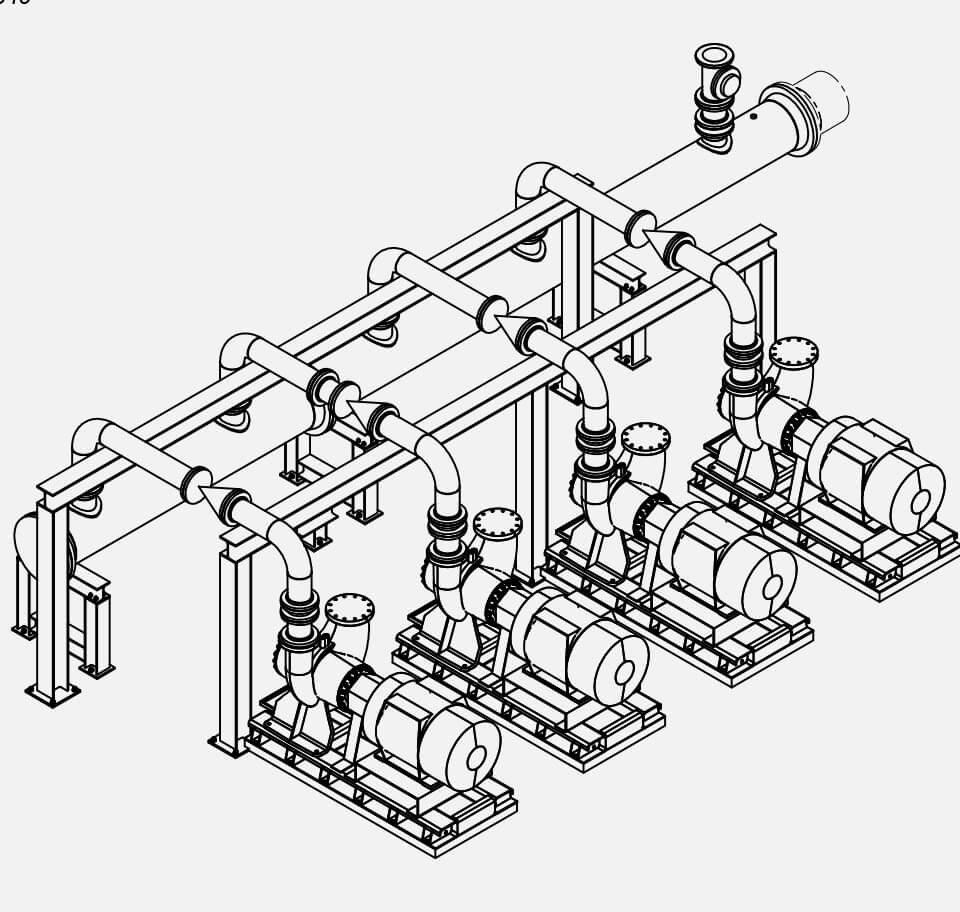

Design of Muhallah Pumping Station

Stress Analysis & Pipe Support Design

WHO WE ARE

Founded on the principle of delivering uncompromising quality, WAGO Engineering was established to provide specialized engineering and fabrication solutions for the Oil & Gas sector in China, the Asia-Pacific, and the wider international market. With core expertise in the design and manufacture of shell and tube heat exchangers, pressure vessels, and distillation columns, we operate in full compliance with ASME, TEMA, and other international codes to meet the stringent demands of our clients.

Headquartered in China, we leverage a diverse pool of technical resources and strong market knowledge to deliver equipment and packages tailored to client specifications. Our fabrication facilities are equipped with certified welding procedures, advanced inspection techniques, and rigorous quality control systems that ensure safety, reliability, and long service life of every unit we manufacture.

Our commitment to continuous improvement, supported by a skilled and multi-disciplined workforce, enables us to execute complex projects efficiently and to develop long-term partnerships with clients built on trust, performance, and repeat business.

Safe, Efficient, Reliable

Mission

Consistently deliver premium quality solutions, within time and budget, without compromising on safety, project specifications and industry standards.

Vision

To become the international EPCC contractor of choice by consistently delivering cost effective, high quality, and on-time solutions.

LET'S WORK TOGETHER

SAFETY, INTEGRITY,ACCOUNTABILITY, GROWTH,

CONTINUOUS IMPROVEMENT

INNOVATION