FEED & DETAIL ENGINEERING

WAGO Engineering has proven its multi-disciplinary expertise in a variety of gas processing and oil refining projects, from inception to successful commissioning and start of production. WAGO Engineering stresses a lot on acquiring, and consequently providing its clients, with workable solutions that help in ensuring that the client’s project is successfully commissioned.

At WAGO Engineering, we specialize in delivering bespoke Front-End Engineering Design (FEED) and Detailed Engineering services tailored for the Oil & Gas sector. Whether you need comprehensive FEED solutions for concept development or intricate Detailed Engineering services for project implementation, we consider the techno-commercial limitations of the target projects and offer viable solutions with the highest IRRs. Our estimation includes CAPEX & OPEX calculations, taking into account the economic, technical, legal, and scheduling considerations, to ascertain the likelihood of completing the project successfully.

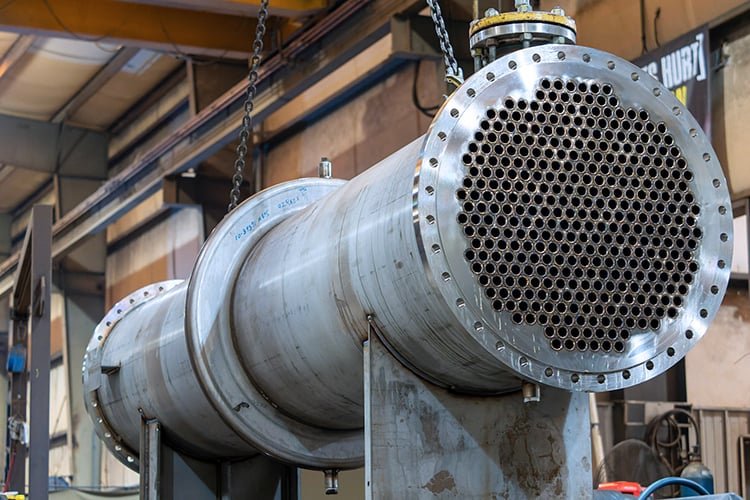

With a diverse team comprising of experienced and creative engineering personnel, we have successfully delivered FEED & Detailed Engineering services for Atmospheric Distillation Units, Vacuum Distillation Units, Naphtha Hydrotreater Units, Isomerization, Fixed Bed Platforming Units, etc. Our engineering solutions are not only economical but also up to par with current best industry practices to ensure the projects are delivered within budget and with the highest standards of quality. WAGO Engineering provides following Engineering services as part of detailed design.

Process Design

WAGO Engineering uses Aspen Hysys, EDR, HTRI, and in-house developed spreadsheets to carry out advanced process simulations and sizing calculations to provide the most optimal design solutions for its clients. With an expert process team, we are able to generate the following deliverables for our projects, among others.

Process Simulations

Equipment Sizing

Line Sizing & Hydraulics

Flare Network Study & Relief Valves Sizing

Piping and Instrumentation Diagrams (AutoCAD, Smart PIDs)

Equipment Datasheets

Heat Exchangers & Air Coolers Thermal Design

Static Design

WAGO Engineering posseses an in-house capability to perform mechanical design calculations for a wide range of equipment using PV Elite, Compress, Ansys (for FEA studies) and other renowned industry tools. Deliverables include the following, among others.

Pressure Vessel Design as per ASME Section VIII (Div 1 & 2)

Tanks Design as per API 650

Spheres as per ASME Section VIII (Div 1 & 2)

FEA Analysis for Equipment & Nozzles

GA & Detail Fabrication Drawings

MTOs, Material Requisitions, & TDCs.

Equipment Datasheets

Project Specifications and Procedures.

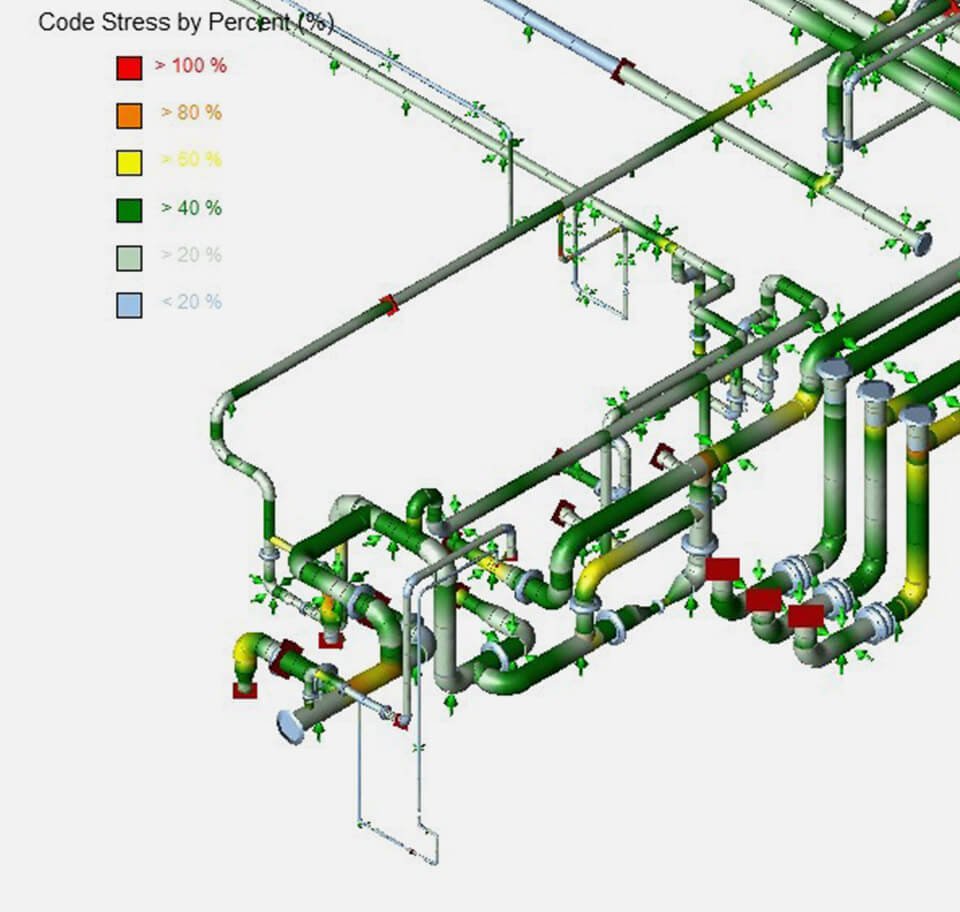

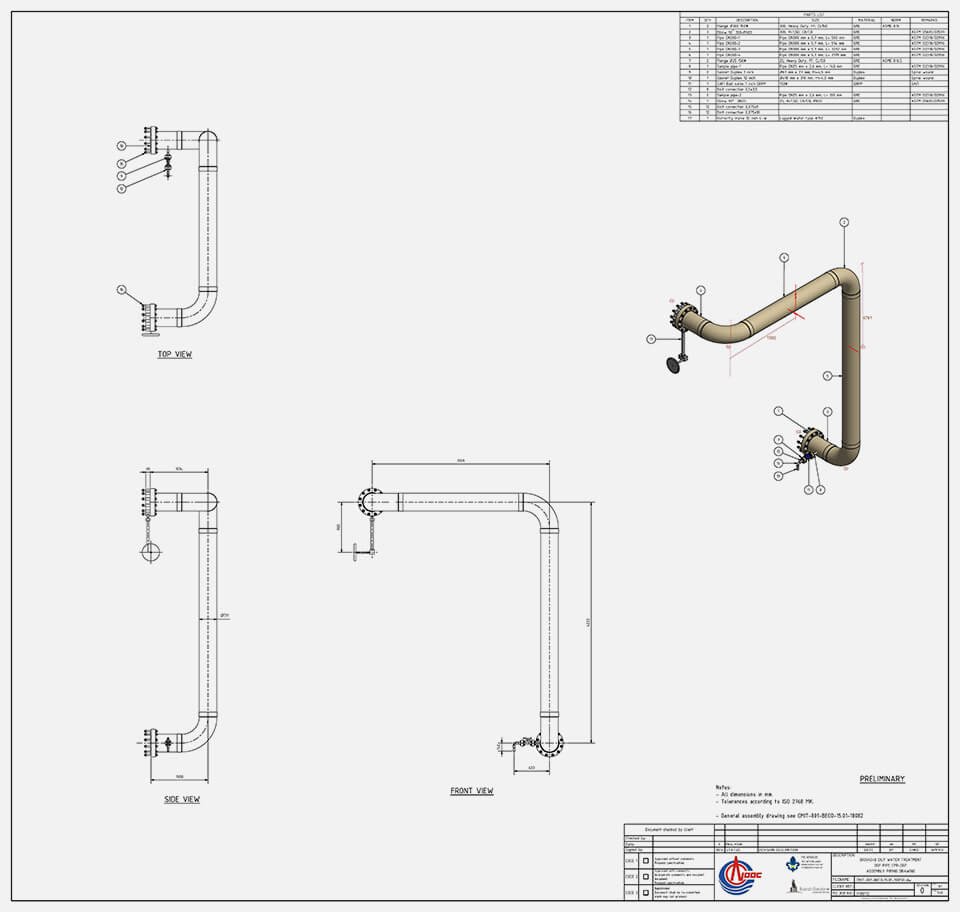

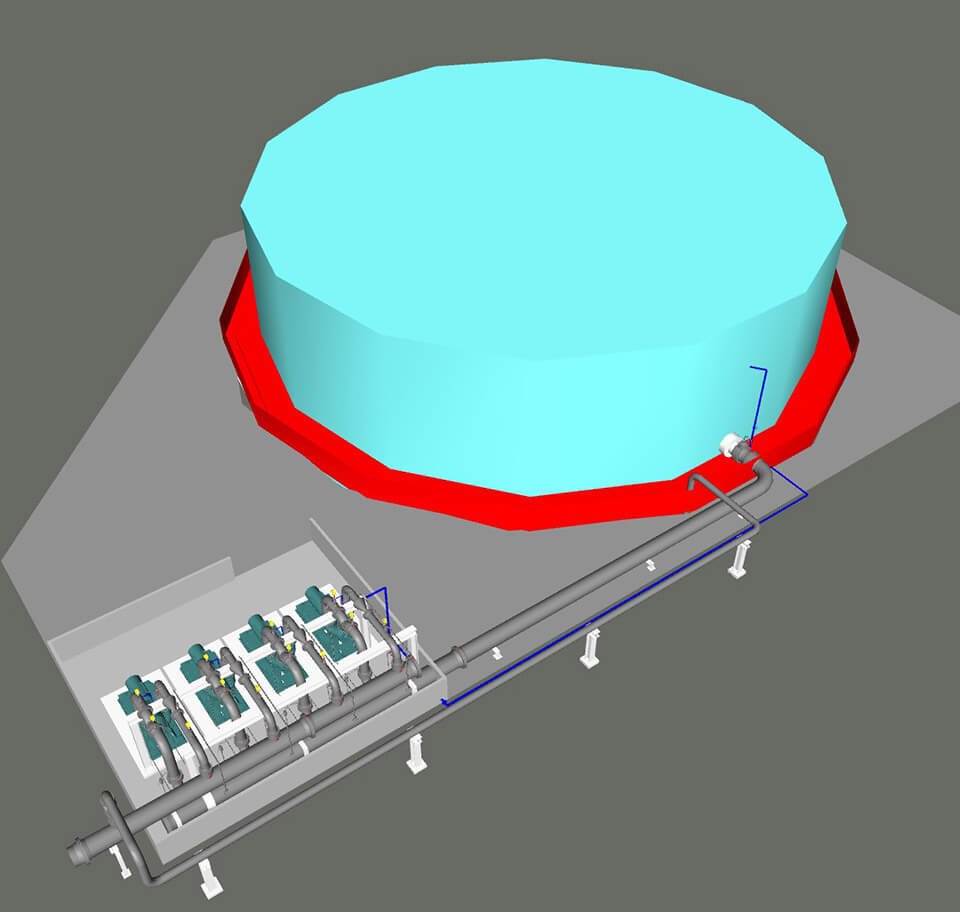

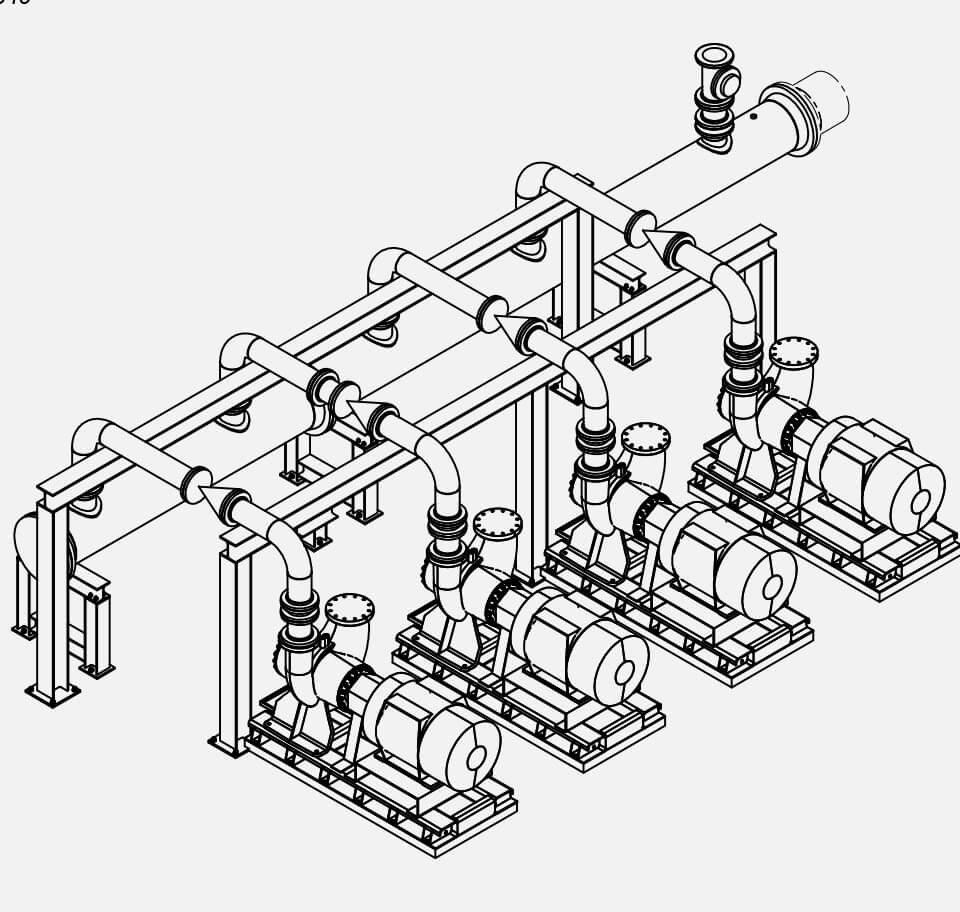

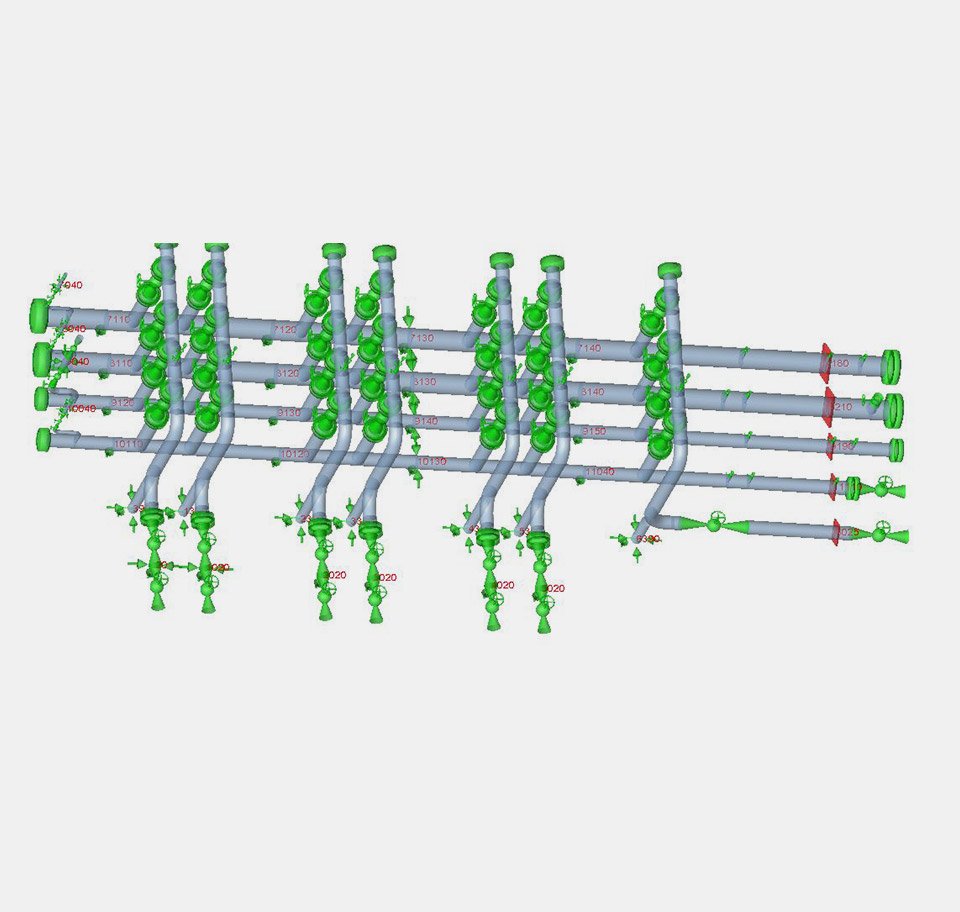

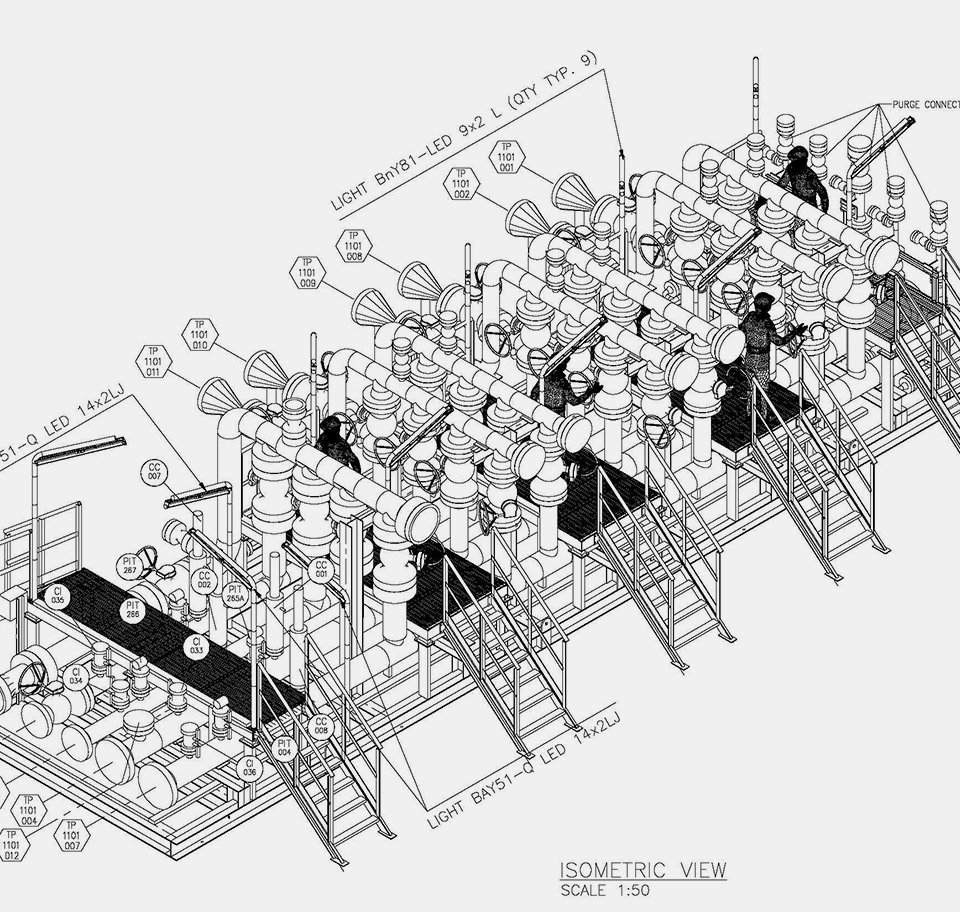

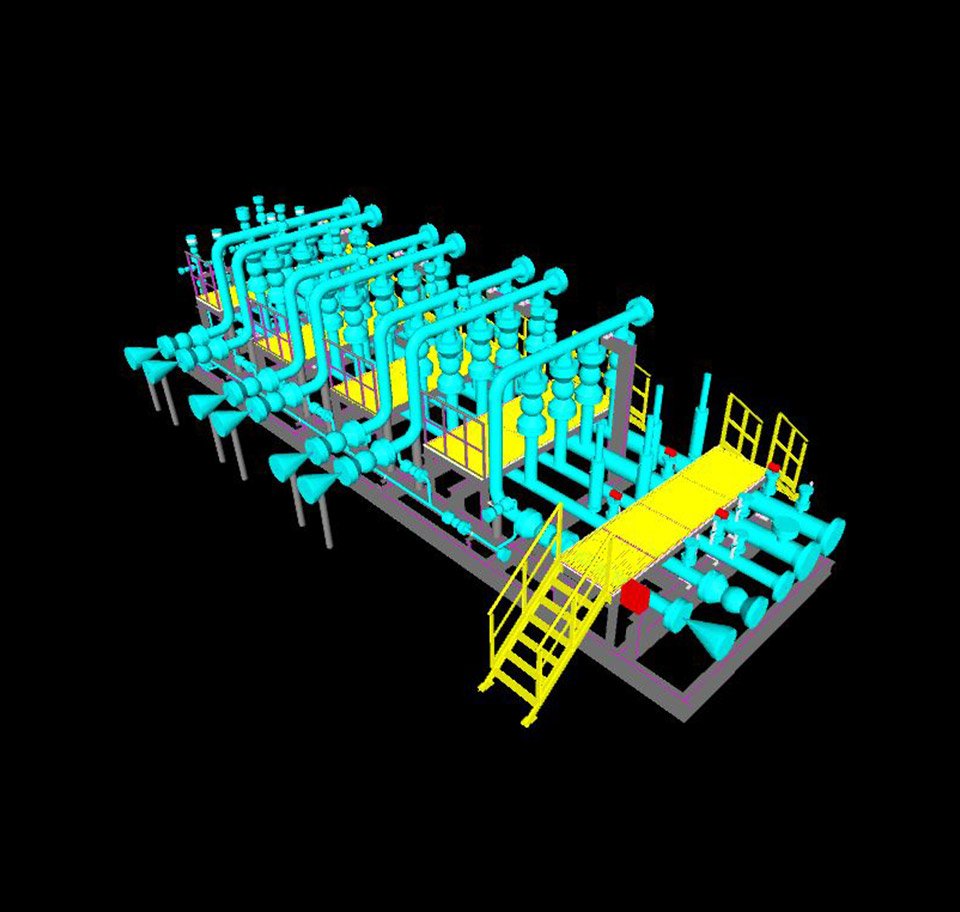

Piping Design

WAGO Engineering possesses the tools and skillset required to develop detailed and comprehensive 3D models for their project, utilizing advanced tools such as Aveva 3D. This enables powerful visualization, clash-free, multi-discipline 3D design, and rapidly generates accurate drawings and reports to reduce costs, timescales and commercial risks of both greenfield and brownfield capital projects. In addition, we are able to utilize CADWorx, Autodesk Plant 3D, Caesar II and other renowned industry software as per project requirements, enabling developemnt of the following key deliverables, among others.

Piping Specifications & Procedures

Datasheets for Valves, Strainers & Specialty Items

2D & 3D Plot Plans

30%, 60% and 90% 3D Model Reviews and Reports

General Arrangement Drawings

Piping Isometrics

MTOs & Material Requisitions

Piping Layouts

Piping Stress Analysis using Caesar II

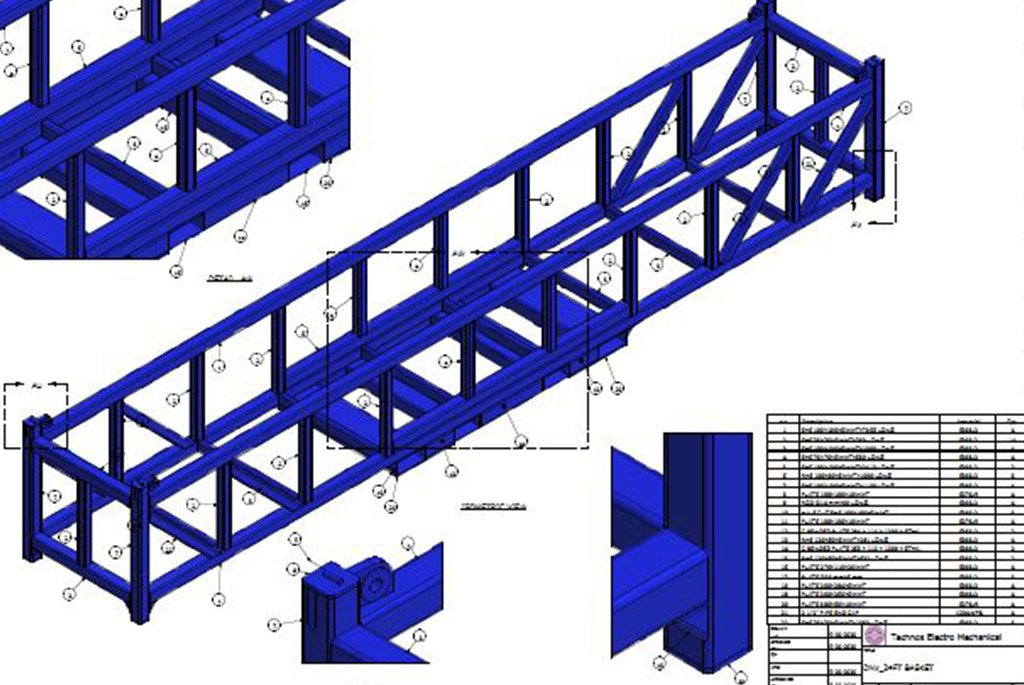

Civil & Structural Design

The following Civil & Structural Design Calculations, Drawings, and Documents are developed as per project requirements.

Structural Design and Analysis of Skids, Pipe racks, etc. using STAAD Pro

Civil Foundation Design & Analysis using STAAD Foundation

Structural Detail Drawings

Civil Foundation Drawings

MTOs & Material Requisitions

Civil & Structural Specifications & Procedures

Electrical Design

WAGO Engineering offers a complete suite of electrical engineering and design services to support Oil, Gas, and Energy projects from concept to execution. Our team ensures all designs comply with international standards, safety requirements, and project specifications, while optimizing efficiency and reliability of electrical systems. With proven expertise in both greenfield and brownfield developments, we deliver detailed engineering deliverables that form the backbone of safe and efficient plant operations.

Power Generators & UPS Design Calculations

Hazardous Area Classifications & Layout

Cable Sizing & Routing Plans

Earthing Calculations & Layouts

Lighting Calculations & Layouts

MCC & Substation Layouts

Transformer Bay

Single Line Diagrams

Specifications and Datasheets

Instrumentation & Control Design

WAGO Engineering delivers specialized Instrumentation & Control (I&C) engineering services that form the backbone of safe, reliable, and automated plant operations. Our expertise extends across process instrumentation, control systems, and safety shutdown systems, ensuring accurate process measurement, efficient automation, and full compliance with international standards. We focus on developing integrated solutions that enhance plant operability, safeguard assets, and optimize overall performance.

Instrument Datasheets

Cause & Effect Diagrams

I/O Lists

Loop Diagrams

Termination Drawings

Control & Shutdown System Design

Functional Design Specifications

F&G Detectors Layouts

Alarm & Trip Matrix

Cable Sizing / Routing Plans